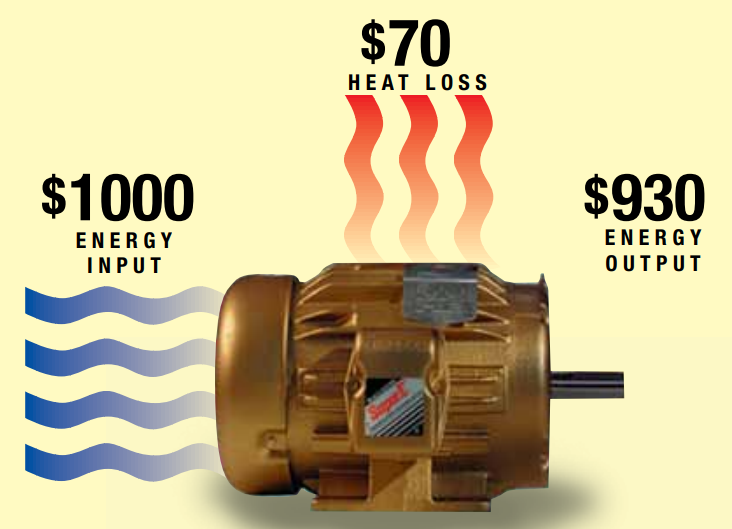

Energy Efficient motors special?

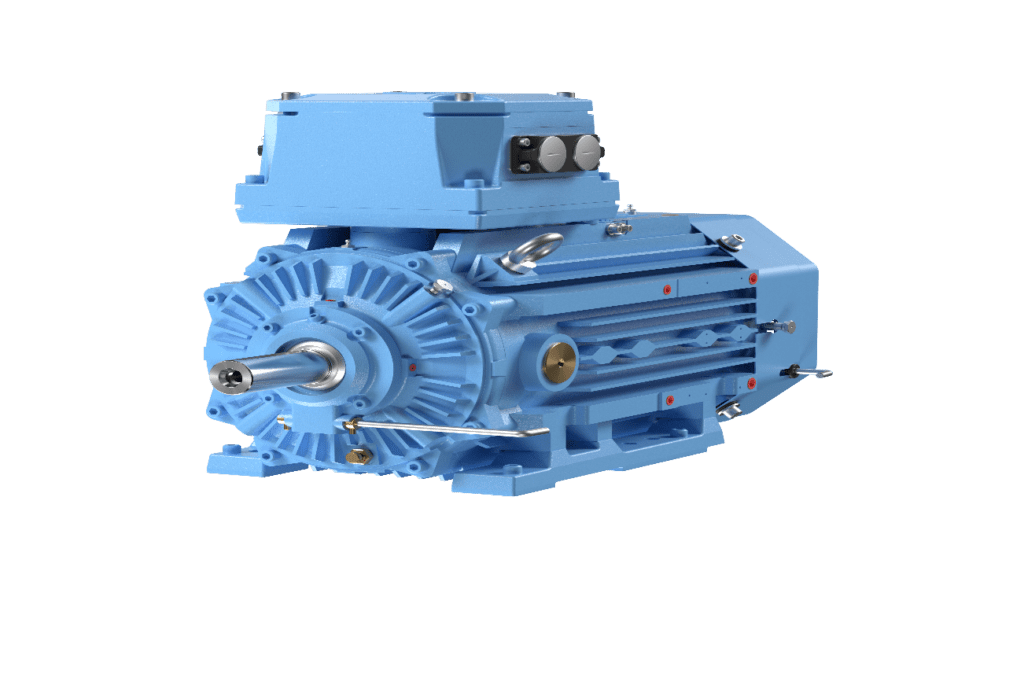

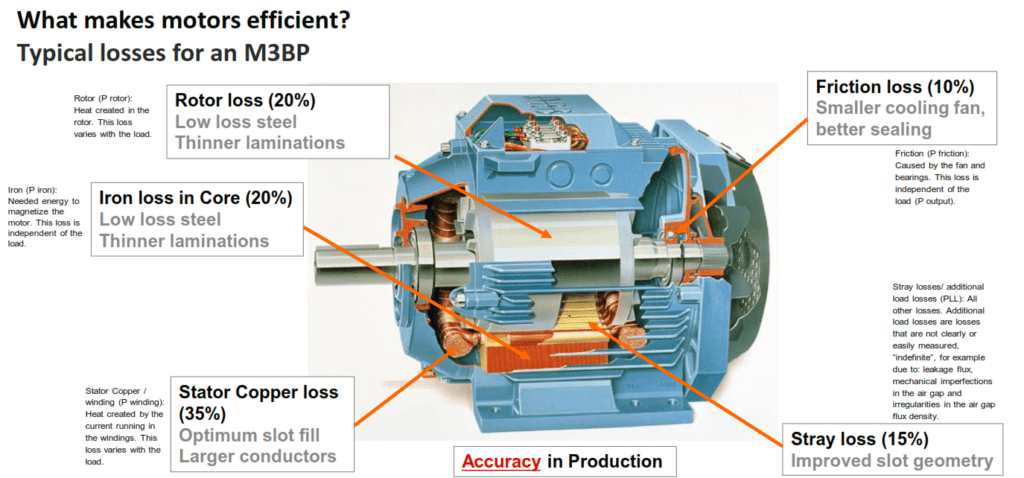

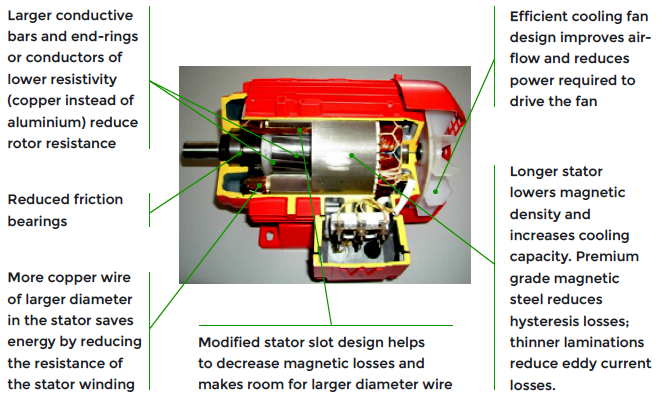

Energy Efficient motor is manufactured using the same frame as a standard motor, but they have some differences:

-Higher quality and thinner steel laminations in the stator

– More copper in the windings.

– Optimized air gap between the rotor and the stator.

– Reduced fan losses.

– Closer machining tolerances.

– A greater length.

– High quality aluminum used in rotor frame.

Application considerations for High Efficiency Motors

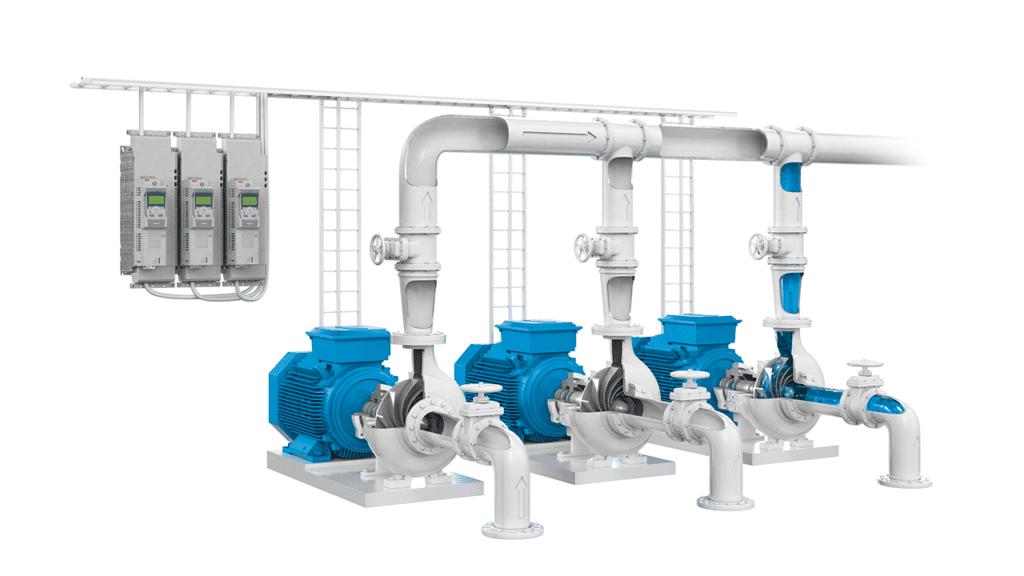

The average speed of an energy-efficient motor can be slightly higher than the average speed of an equivalent-sized standard-efficiency motor. Installing a new motor with a higher speed can result in reduced energy savings. For centrifugal pump or fan applications in particular, it is important to select a replacement motor that has a comparable full-load speed. It is also important to replace induction motors with induction motors and other types with their corresponding equivalent. Seek specialist advice if you want to change motor types.

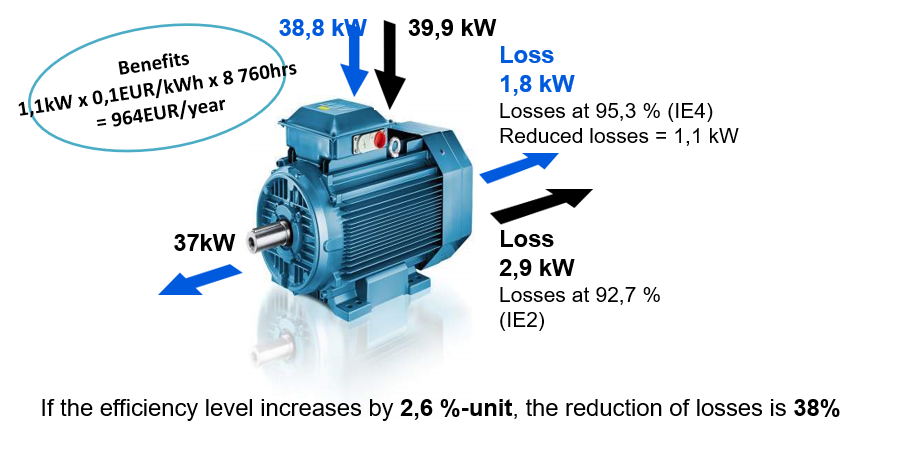

Here are the typical technical and commercial questions asked when assessing the viability of energy efficient motors for your operation.