Around 19 % of Global electricity is used to light our world the second largest after the electric motors which accounts for about 28 % global electricity consumption.

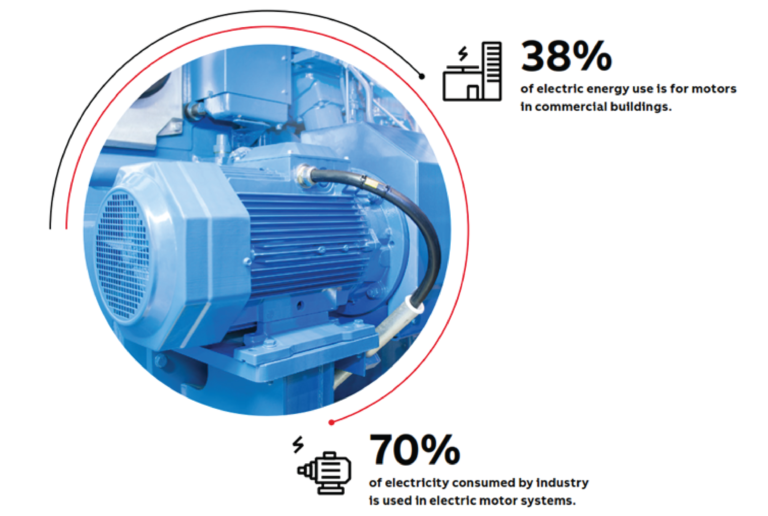

⦁ Nearly 38 % of electric energy use is for motors in commercial buildings and about 70 % of electricity consumed by industry is used in electric motor system.

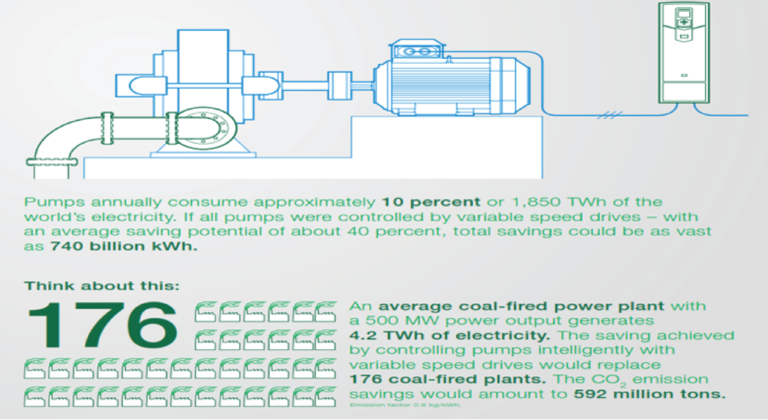

⦁ Roughly 75% of the industrial motors in operation are used to run pumps, fans, and compressors, a category of machinery that is highly susceptible to major efficiency improvements. When added to the existing motor of a pump, fan or compressor, a variable speed drive can typically reduce power consumption by 25%

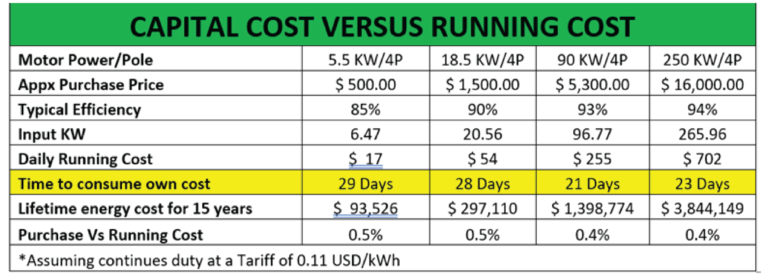

⦁ It takes only appx 20-30 days to consume, its own capital cost of an electric motor.

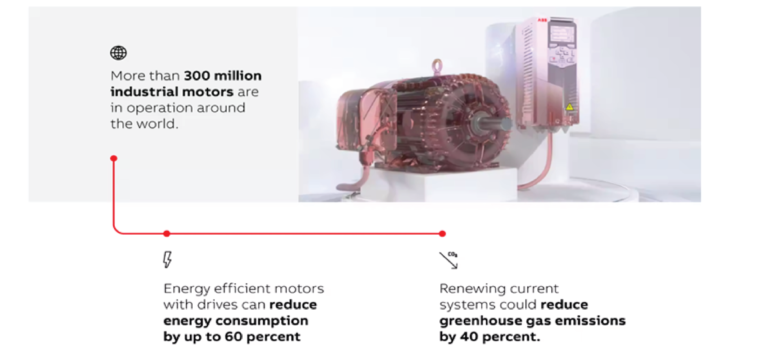

⦁ It has been estimated that, if all of the more than 300 million industrial electric motor-driven systems currently in operation were replaced with optimized, high-efficiency equipment, global electricity consumption could be reduced by up to 10 percent.

⦁ Pumps are one of the most common motor applications and offer the biggest potential for saving energy.

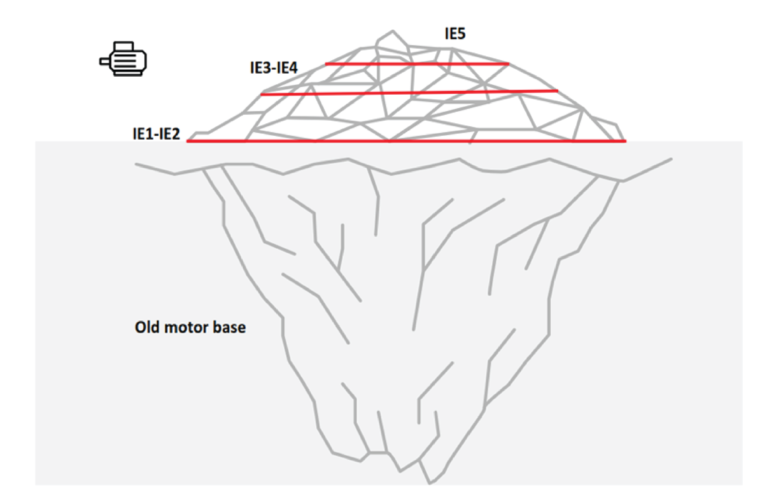

⦁ Only a small fraction of all motors complies with IE2 efficiency of motor of today

⦁ More than 300 million industrial electric motors are operation around the world and most of these industrial electric motors in operation are more than 10 years old?

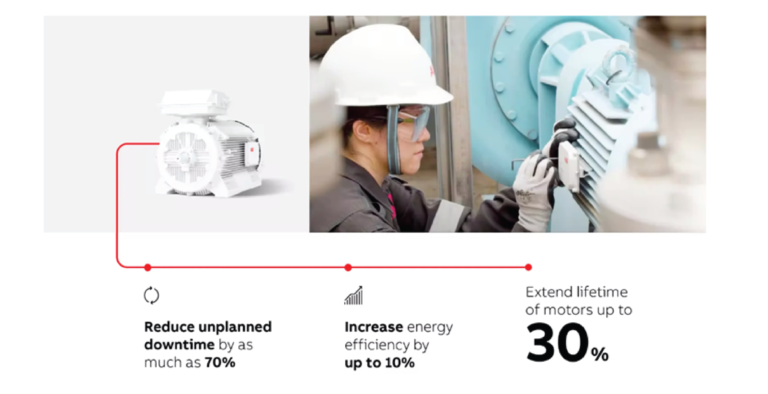

⦁ A smart sensor, about the size of a smartphone, can convert traditional electric motors into smart, wirelessly connected devices?